Issue #26 - Deciding on a Dispensing Valve

05/11/2017

April 27, 2017

April 27, 2017

Seven Different Dispensing Valves: Where Does Each Work Best?

by Robert Campbell - Product Line Manager, Fisnar Europe

Understanding how valves work and interact with the material they dispense makes it easier to select the right one. Selecting a valve that will apply a lubricant, adhesive or coating calls for at least

three considerations: knowing how valves work, fluid characteristics and how the material will be applied.

Although this sounds simple, it's complicated by at least seven different basic pneumatic valves, fluid characteristics that vary and applications that call for sprays, dots or thick lines. A little study, however, can simplify the selection.

Click here to download the full article "Seven Different Dispensing Valves".

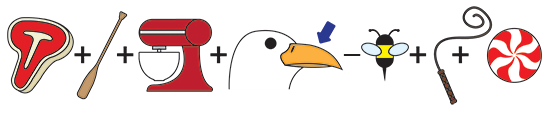

Pictogram Puzzle

A puzzle describing related products, applications, etc. The answer can be found at the bottom of the newsletter. Enjoy!

Product Spotlight:

MicroCare SuprClean™ Clear is a powerful, heavy-duty circuit cleaner and degreaser that can be used on a variety of materials such as PVC, nylon, epoxies, polypropylenes, and polyethylenes. It has versatility, low odor, non-flammable, and instantly dries. Comes in a 12oz aerosol can.

Click here to learn more and purchase MicroCare SuprClean MCC-SPR

Upcoming Events

SoCal Aerospace Expo

May 11-12, 2017

LA Convention Center in

Los Angeles, California

SAMPE 2017

May 23-24, 2017

Washington State Convention Center in Seattle, WA

Henkel Medical CTS

May 17, 2017: 10AM-3PM

Residence Inn Pittsburgh North Shore in Pittsburgh, PA

Henkel Medical CTS

May 23, 2017: 9AM-1:30PM

DoubleTree by Hilton Minneapolis North in Minneapolis, MN

Pictogram Puzzle Answer:

Meter Mix Equipment

Meter Mix and Dispensing systems precisely measure, blend, control and dispense adhesives and specialty chemicals with uniform accuracy and reliability. They work with single and multiple component materials including epoxies, polyurethanes, silicones, acrylics, urethanes, pastes, abrasive- or microsphere-filled materials and more. Meter Mix Systems are available in benchtop, cart-mounted, or full workstation sizes.

Learn more about Meter Mix Equipment